As the objective of a course in Machine Design & Manufacturing, I built a Stirling engine from scratch. The primary skills I developed were in:

- Solidworks

- GD&T

- CNC mill & lathe operation

- Manufacturing assembly

We were given fixed engineering drawings for certain parts and allowed creative freedom with the rest. In order to ensure our choices would result in a functioning engine, we modeled each component and the full assembly in Solidworks for verification.

[awaiting solidworks images]

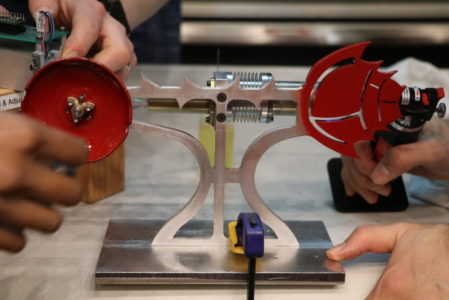

We honed the basics of operating a CNC mill and lathe in practice with standard fixed parts like a mounting block and piston flange. We then moved to customized components like the flywheel, hub and bed plate. I chose a flower inspired flywheel which required learning how to program a 3-axis CNC mill. An interesting challenge came with designing a balance weight that would work with my flywheel to align the system’s moment of inertia.

My engine reached a max speed of 683rpm at our final expo.

After some post-run analysis, I’m fairly sure I could increase my engine’s speed to above 1000rpm with a couple tweaks to the aforementioned balance weight. We live and we learn, I suppose.